The Project

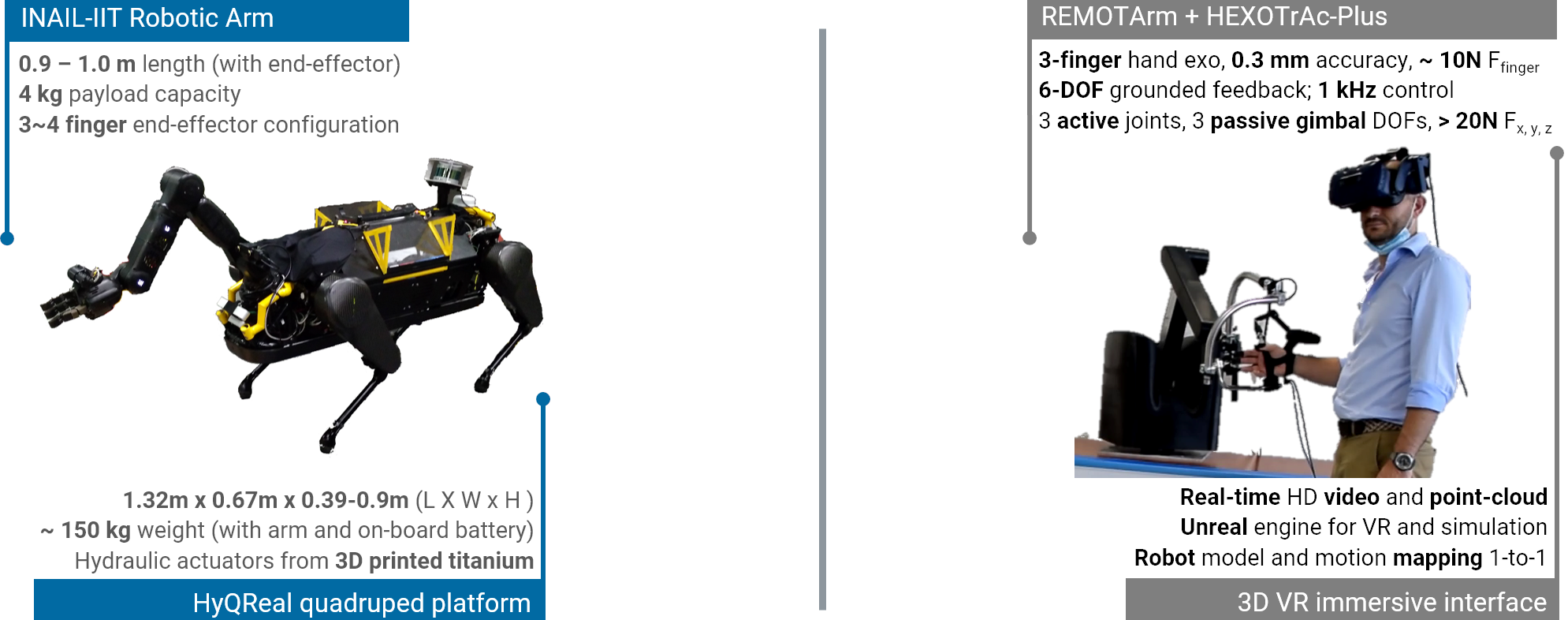

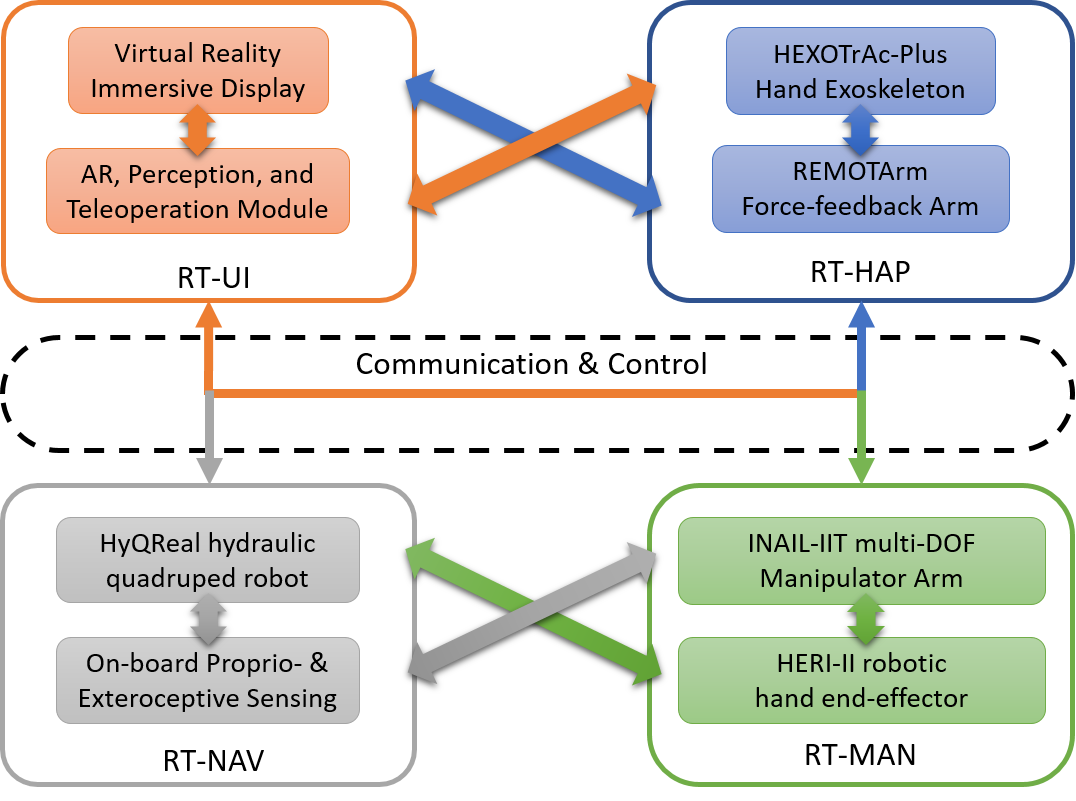

The Robot Teleoperativo project, in collaboration with INAIL (“Istituto Nazionale per l'Assicurazione contro gli Infortuni sul Lavoro” - National Institute for Insurance against Workplace Injuries, Italy) CUP J32F17000950005, is aimed at the development of a novel, collaborative teleoperation hardware and software system dedicated to operating in certain hazard-prone industries, reducing the risks to the workers’ safety and well-being. It utilizes, develops, and integrates advanced technologies in tele-locomotion, tele-manipulation, and remote human-robot interaction.

The project builds on the existing technological expertise and capabilities at IIT, and involves THREE distinct research lines, contributing the know-how in locomotion, perception and visualization, manipulation, and teleoperation.